Victor automatic weighing packing machine consists of automatic weighing, conveyor, sewing,filling and heat sealing devices for feed pellet,powder materials,grains,and wood pellets. In other words, the automatic feed pellet packing machine is composed of weighting, conveying and packing systems and intelligent controller.This pellet packing machine is a combination of automatic weighing and filling, together with transportation sewing machine. Therefore, the pellet packing machine is able to automatically weigh, fill and sew wood pellets with various sizes.

automatic pellet packing machine is composed of these parts: automatic weighing device, transmission device, sewing device and the electric control system. The automatic weighing device is designed with two parted weigher. They can work together or separated in weighing procedure. Once one of the weigher is broke down, the other will work continuous to avoiding production halts.

The sewing device is used to Seal the bags after the feed pellets is weighed and poured into the bags. The transmission device is used to transmit the packed pellets bags away from the automatic weighing packing machine. And all these steps are under the control of the electric control system. Reliable and efficient, the pellet packing machine has a wide application in wood pellet plant, feed pellet production line, sugar processing industry and many other industries.

Automatic Feed Pellet Packing Machine Application

The automatic feed pellet packing machine is suitable for large and medium sized feed pellet production plants. It is always applied to a automatic weighing and packing system combined with the transport mechanism and the sewing machine. The automatic weighing packing machine can pack feed pellets, wood pellets, fertilizer granules and other particle material and powder material with good fluidity. With an excellent performance, it has been adopted by a great many large feed pellet production factories.

Remarkable Features of Automatic Feed Pellet Packing Machine

1. Automatic pellet packing machine has the advantages of high calculating precision, stable function, digital demonstration and easy operation.

2.Equipping the computerized control software, the feed pellet automatic weighing packing machine is available for control data setting,drop height auto-repairing, fault auto-detection.

3. Adopting the duple weigher working system. The two weigher can work synchronous or individual, which improves the working efficiency of the feed weighing and packing machine.

4. Using the international advanced sensor and the pneumatic actuators, the feed pellet weighing and packing machine works reliably, with no pollution.

5. The out surface applies the plastic spraying technics besides the inner surface applies the advanced stainless steel material, against rusting and corrosion thus prolonging the service life of the automatic machine.

6. The feed pellet automatic weighing packing machine reserves communication interface, by which the whole machine can implement the digital connection with the upper machine in the feed pellet production line.

7. The automatic hot printer, automatic sewing machine is optional to equip according to your requirement.

8.Computer high-speed feeding sampling and processing, together with the programmable control process ensure that it is universal to different packing.

9.This pellet packing machine has a three-speed feeding system, which guarantees weighting speed and weighting accuracy.

10.The bagging machine’s special aseismic equipment guarantees precise calculation, fast speed and stable work under bad conditions. It can be adjusted outside and it is very convenient to maintain.

11.This automatic pellet packing machine’s belt feeder type with single weighing hopper provides a complete bagging and packing arrangement. automatic weighing packing machine is available for a wide range of sizes.

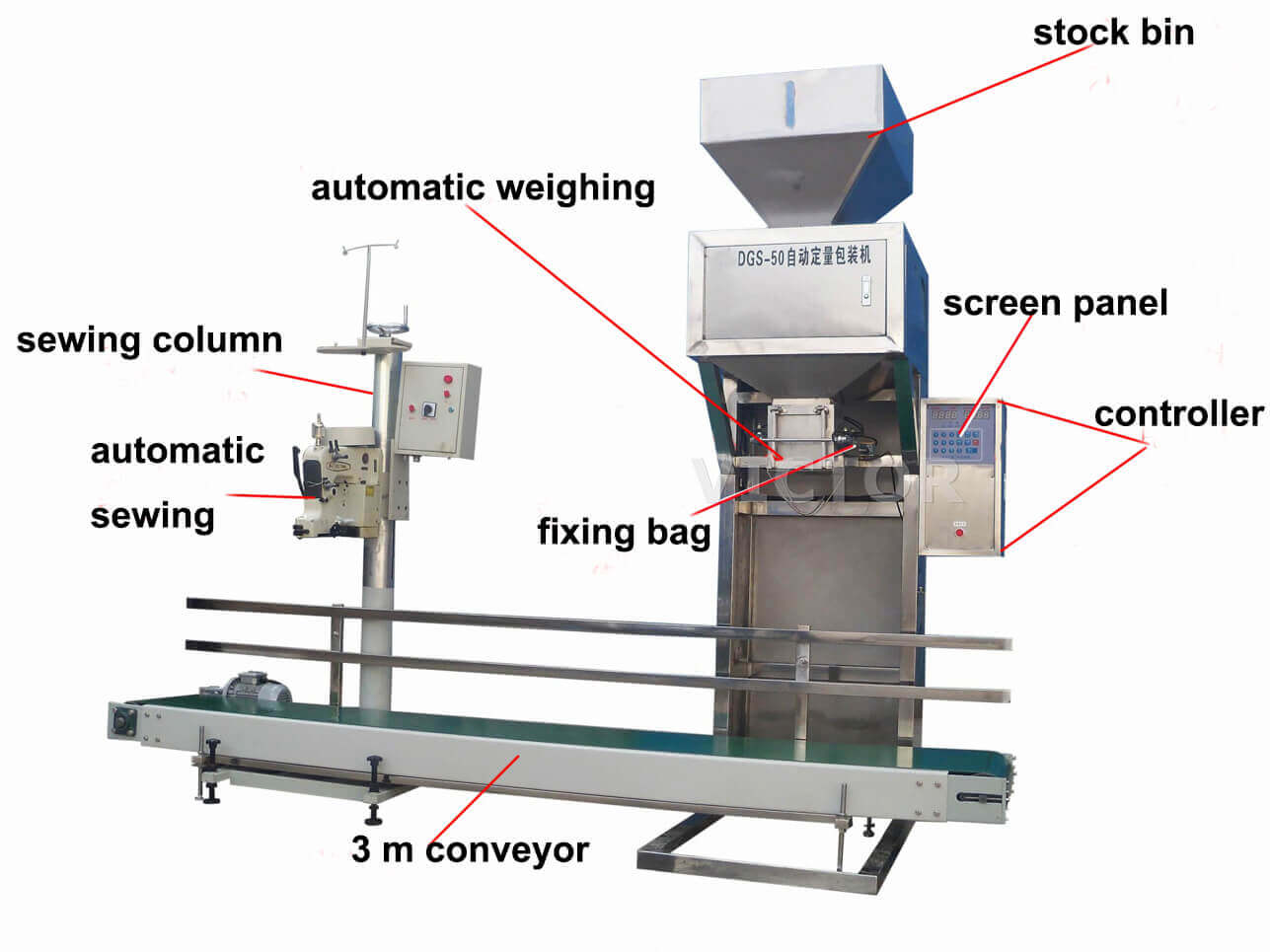

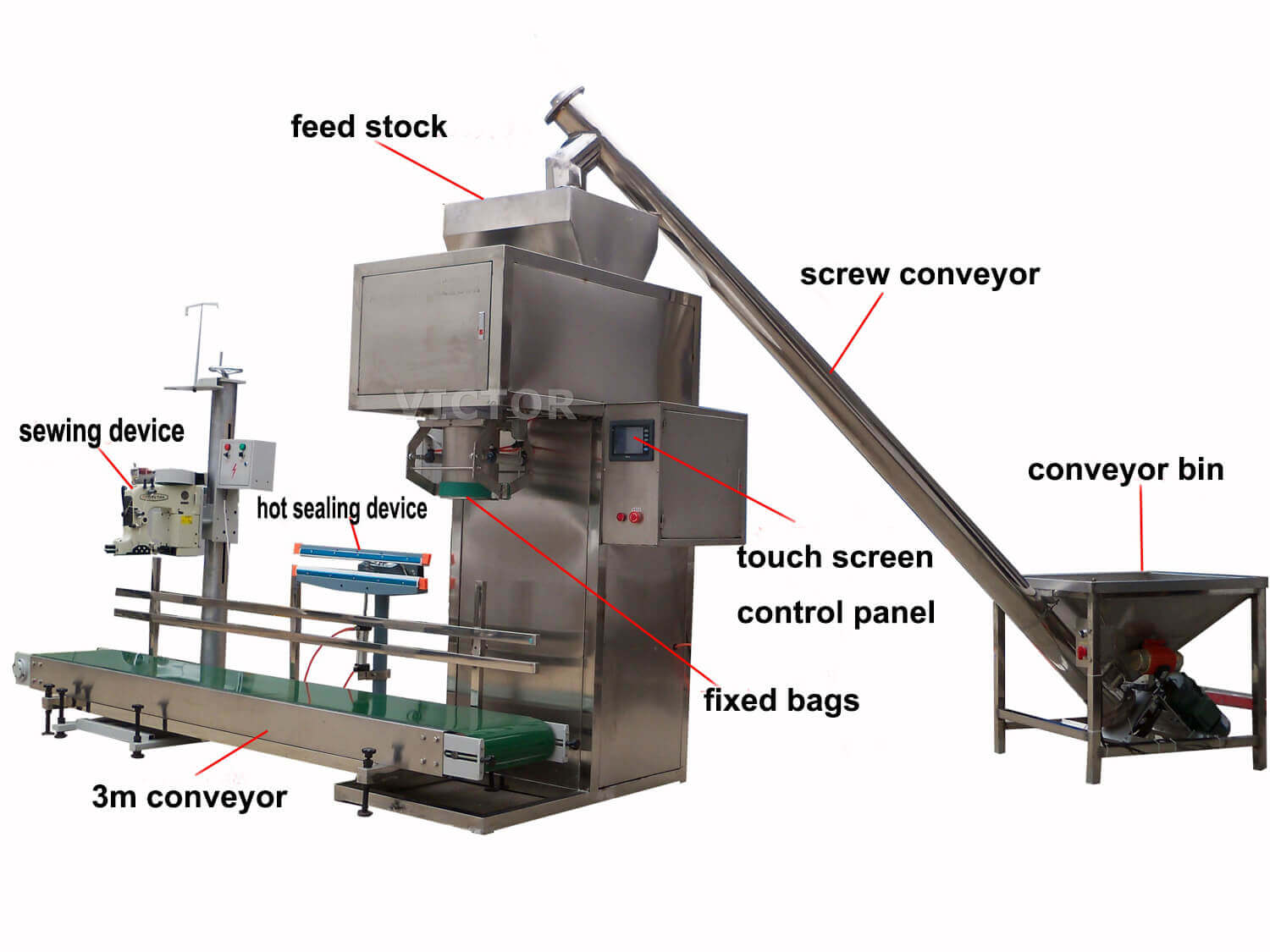

Composition of automatic weighing packing machine

The automatic weighing packing machine, as the core part of the automatic weighing and packing system, is composed of these five parts: storage bin, weigher(s), control system,transporting device,and sewing device.

Storage Bin: The storage bin is used to take over the feed pellets or other particle materials to weigh and pack and to store them temporarily for further processing.

Weigher(s): By setting data, the weigher(s) can weigh specific weight of pellet material.

Control System: It is the brain of the pellet weigh and packing machine. With the control system, the packing machine works automatically and accurately.

Sewing device:The sewing device is used to Seal the bags after the biofuel pellets is weighed and poured into the bags

transporting device:The transmission device is used to transmit the packed pellets bags away from automatic pellet packing machine

automatic pellet packing machine parameters

Packing specification: 5-50kg

Maximum weighing weight : 100kg

Packing speed: 4-6 bags / min

Packing accuracy: ±0.2%

Air source pressure: 0.4-0.6Mpa

Gas source consumption : 0.5Nm3/mi

Weighing method : sensor

Frequency/voltage: 50Hz/60Hz/220V/380V

Equipped with power: 1.1KW

Dimensions: 800 × 900 × 1900